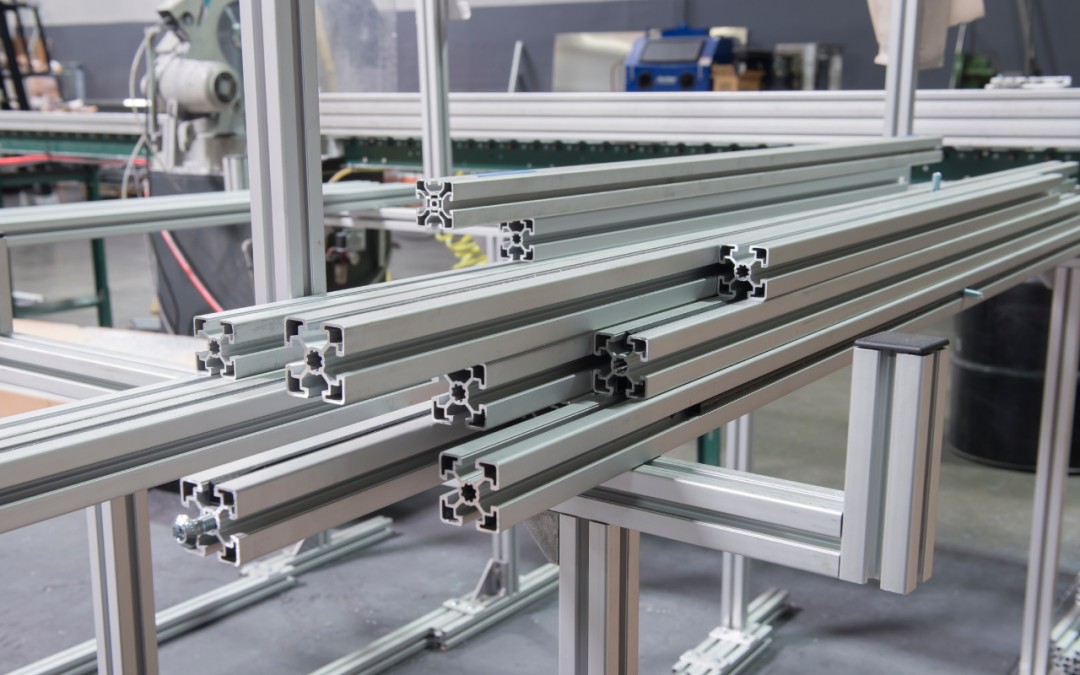

Walk into almost any modern manufacturing space and you’ll see sleek, silver frameworks supporting everything from conveyors to workstations. Those structures are built using aluminium profiles, the modular building blocks that have quietly revolutionised industrial design.

Their strength, versatility and clean aesthetic make them ideal for a wide range of engineering projects. Whether you’re assembling a prototype or creating a full production line, aluminium profiles can adapt to the task.

Let’s take a closer look at how they’re used across different industries and why they’ve become the go to choice for engineers and technicians worldwide.

A Foundation for Precision Workbenches

Every efficient workshop starts with a reliable workbench. Aluminium profiles make it easy to build benches that are customisable, ergonomic and scalable.

Unlike traditional welded steel benches, aluminium systems can be reconfigured as needs evolve- simply loosen a connector, slide in a new component and retighten. Shelves, tool holders and even lighting systems can be integrated directly into the frame using the T-slot channels.

This adaptability is perfect for lean manufacturing environments, where flexibility and continuous improvement are essential.

The Backbone of Machine Frames

When it comes to machinery, stability and precision are everything. Aluminium extrusions form the structural backbone of automation systems, conveyors and CNC setups.

Their rigid yet lightweight design allows for heavy loads without the excessive bulk of steel. The T-slot profile also makes it easy to attach motors, guards, sensors and control panels- simplifying assembly and maintenance.

In short, aluminium frames combine strength with accessibility, making them an ideal foundation for industrial automation and production equipment.

Safety Enclosures and Guarding Systems

Protecting workers and machinery is a top priority in any facility. Aluminium profiles provide a clean and professional solution for safety guarding, barriers and machine enclosures.

Panels made from polycarbonate, mesh, or acrylic can be mounted directly onto profile frames. The result is a lightweight yet durable safety structure that maintains visibility and complies with workplace safety standards.

The modular design also means guards can be expanded, relocated, or repurposed without costly redesigns, perfect for dynamic production environments.

Mobile Racks, Trolleys and Handling Units

Efficiency often depends on mobility. Aluminium’s light weight and strength make it an excellent choice for trolleys, transport carts and storage racks.

These can be fitted with castors, adjustable shelves and handles, offering smooth movement around the factory floor. Because they’re built from the same modular system, these mobile solutions integrate seamlessly with other aluminium-framed equipment, creating a unified, ergonomic workspace.

Prototyping and Testing Applications

In R&D and education, the ability to modify quickly is priceless. Aluminium profiles enable rapid prototyping, allowing teams to experiment with different configurations without starting from scratch.

When a test setup or pilot rig needs adjusting, components can be reused, reducing waste and cost. For engineers and researchers, this flexibility supports innovation while maintaining precision and professional build quality.

Frequently Asked Questions

Are aluminium profile projects durable enough for industrial use?

Yes. When built correctly, aluminium frames can handle substantial loads and vibration, making them suitable for both light and heavy duty applications.

How easy is it to modify an existing aluminium frame?

Very easy. Because the connections are mechanical, frames can be expanded or redesigned using basic hand tools, no cutting or welding required.

Can aluminium profiles support motors or heavy equipment?

Absolutely. With the right cross section and connectors, aluminium frames can safely carry motors, conveyors and robotic systems.

Q4: Are aluminium profile systems sustainable?

Yes. Aluminium is 100% recyclable and reusable, which makes modular profiles an environmentally friendly option.

Final Thoughts

From custom workbenches to industrial machine frames, aluminium profiles deliver a rare combination of durability, precision and reusability. Their modular construction supports rapid assembly, easy modification and long term reliability, exactly what modern industries demand.

For engineers looking to improve factory efficiency, build ergonomic workstations, or develop lightweight modular structures, high quality aluminium profiles remain one of the most versatile and cost-effective materials available today.